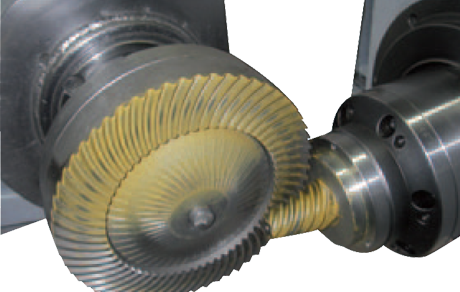

MS-Graessner manufactures high-quality bevel-gears using the Gleason process. Each milled tooth system is manufactured in accordance with DIN 3965 in gear quality ≤ 7 and ground tooth systems in accordance with DIN 3965 in gear quality ≤ 5.

Advantages of MS-Graessner Bevel Gears

- High level of coverage due to the fact that several teeth are meshed simultaneously

- Resistant to elastic deformation of gears, shafts and bearings

- Circular arc gear teeth are more resistant to bending than straight and oblique gear teeth

- Very gentle transmission even at high-speed operations and under heavy loads

- Noise and oscillation dampened even at high peripheral speeds

- Gear sets can be assembled in your preferred direction of rotation

- Greater than 97% efficiency

- Due to convex tooth-loading, the load is not concentrated on tooth ends

- All gear sets can be lapped in pairs upon request

Comparison of Gears

Spiral Bevel Gears

Spiral bevel gears have curved teeth at an angle allowing tooth contact to be gradual and smooth. Spiral bevel gears utilize helical teeth formed along spiral lines on the gear face. The main advantage of spiral gears over straight gears is the smoothness of operation as the teeth engage more gradually.

Hypoid Bevel Gears

A hypoid gear is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear. Hypoid bevel gears are similar to spiral bevel but the pitch surfaces are hyperbolic and not conical. The pinion can be offset above or below the gear center, thus allowing larger pinion diameter, longer life and smoother mesh.

Zerol Bevel Gears

Zerol bevel gears are spiral bevel gears with a zero degree central spiral angle - a combination of spiral- and straight-tooth bevel gears. Zerol bevel gears are designed with the intent of duplicating the characteristics of a straight bevel gear but they are produced using a spiral bevel cutting process. The teeth are curved, but not angled.

Applications

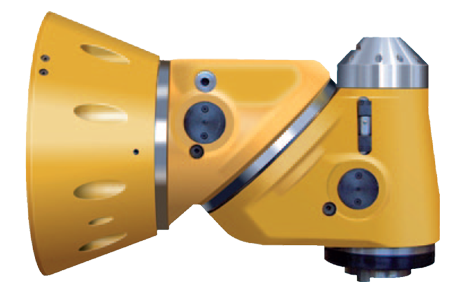

Markets Served: life tools, robotics, industrial tools, machine tools, gear boxes, handling modules, and many more!

All of our gear products can be customized to your precise specifications. Contact us today and let us know what you need. We can make our gears work for you.

| Spiral Bevel Gear | Hypoid Bevel Gear | Zerol Bevel Gear | |||

|---|---|---|---|---|---|

| For transmitting forces at an angle | |||||

| At high torques | |||||

| At low torques | |||||

| Under heavy load | |||||

| Under light load | |||||

| For low-noise operation | |||||

| For low-vibration transmission | |||||

| For drives that have input and output on the same level | |||||

| For drives that have input and output shaft axially offset | |||||

| For unusually high gear reduction | |||||

| If the pinion is to be as large as possible | |||||

| For all applications with space and weight limits | |||||