Looking for a custom solution?

MS-Graessner has been a worldwide leader in manufacturing custom gears and gearboxes for 60 years. Contact us now

Only Satisfied with the best solution, not the first one that comes along.

MS-Graessner's engineering and special manufacturing techniques have helped them become a leader in precision manufacturing of standard and customized gears, tooth systems and gearboxes.

Individual solutions are a standard at MS-Graessner. Instead of offering expertise that's confined to certain areas, MS-Graessner offers comprehensive knowledge in all relevant areas - from specifications and the first sketch up to the manufacturing of the zero series including intensive test operations.

MS-Graessner's expertise also extends to a special in-house developed workflow management system for optimal processes between all areas involved and the customer. The quality management system guarantees the highest quality products.

Why should you choose MS-Graessner?

- 60 years of industry experience

- High precision manufacturing

- Customization of any gear and gearbox

- High torques and high speeds

- Low-noise gears

- Forced lubrication

- Low ratios

- Production process and techniques lowers overall costs

- Options for the food and beverage industry

- DIN EN ISO 9001 and 14001 certified

MS-Graessner Engineering

Designing

Utilizing customized and specialized software, MS-Graessner calculates and optimizes every possible aspect and component.

- GEARFOX - Drive train calculation

- KISSsoft - Designing & optimization

- Gleason - Toothing calculation

Production

State-of-the-art CNC milling and grinding machines ensure that MS-Graessner offers only the highest precision and highest quality products.

- Only the newest and best equipment

- Hardened and precision ground gears

- Grind both sides of gear teeth at once

Component Testing

Digitally networked, CNC-controlled measuring equipment provides precise information about tolerances and run outs of drive sections.

- 3D measuring of gears and gear teeth

- Tooth-contact analysis

- Roundness control

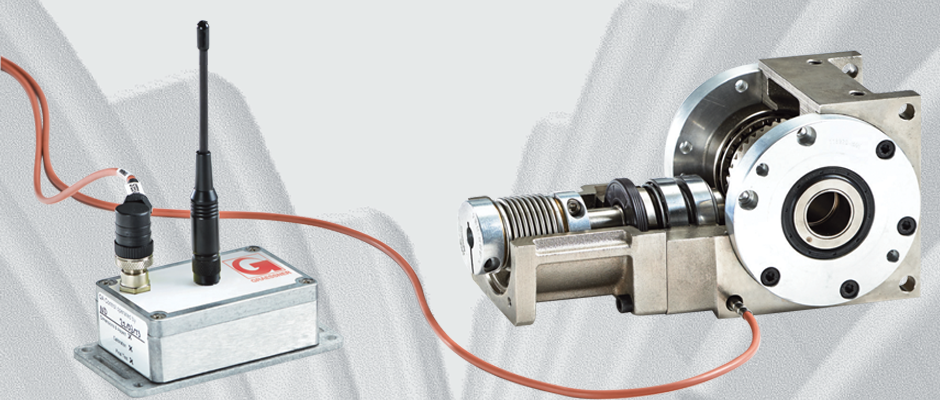

Assembly & Testing

Before it reaches you, MS-Graessner puts your gearbox through hell by testing the assembled gearbox under extreme and normal usage conditions.

- Simulations with and without loads

- Extensive sound & temperature tests

- Continuous and cycle operation tests